2017 Journal Issues April 1, 2017

Special Issue: Additive Manufacturing of Radio-Frequency Components

Volume 105, Issue 4

April 2017

Guest Editors

Guest Editors: Roberto Sorrentino, Petronilo Martin-Iglesias, Oscar Antonio Peverini, and Thomas M. Weller

Special Issue Papers

By R. Sorrentino, P. Martin-Iglesias, O. A. Peverini, and T. Weller

By F. Calignano, D. Manfredi, E. P. Ambrosio, S. Biamino, M. Lombardi, E. Atzeni, A. Salmi, P. Minetola, L. Luliano, and P. Fino

This paper presents an overview of the main additive manufacturing/ 3-D-printing technologies that are suitable for many satellite applications, and in particular RF components. These technologies represent potential solutions for low-volume manufacturing of high value and highly complex parts and products.

By P. Booth and E. Valles Lluch

This paper presents complex layouts of resonators and coupling elements aimed at enhancing the performance of all-metal waveguide filters manufactured through selective laser melting. Qualification of Ku-band filters for space-borne applications is demonstrated.

By O. A. Peverini, M. Lumia, F. Calignano, G. Addamo, M. Lorusso, E. P. Ambrosio, D. Manfredi, and G. Virone

This paper focuses on the applicability of the selective laser melting process to the development of microwave waveguide devices for satellite telecommunications. Upon the assessment of the electromagnetic properties of components manufactured through this process, a robust design of Ku/K-band filters is experimentally validated.

By T-H. Chio, G-L. Huang, and S-G. Zhou

In this paper, the authors describe the advantages of implementing microwave waveguide components through direct melting laser sintering. Efficient implementation of complex X/Ku-band layouts that are difficult to fabricate using conventional machining is demonstrated.

By J. Maas, B. Liu, S. Hajela, Y, Huang, X. Gong, and W. J. Chappell

This paper describes how stereolithography (STL) has been used to manufacture high-performance microwave circuits such as high-quality factor resonators and filters, the integration of STL with conventional printed circuit board fabrication, and the versatility it provides for advanced instrumentation development.

By J. S. Silva, M. García-Vigueras, T. Debogovic, J. R. Costa, C. A. Fernandes, and J. R. Mosig

This paper presents additive manufacturing as an enabling technology to realize high-performance and low-cost antennas for Ka-band applications. Two different antennas for Ka-band satellite communications are presented, both fabricated using a stereolithographic (SLA) AM process followed by metal coating.

By A. I. Dimitriadis, T. Debogovic, M. Favre, M. Billod, L. Barloggio, J.-P. Ansermet, and E. de Rijk

This paper presents an approach for additive manufacturing of complex waveguide feed networks using a combination of polymer stereolithography and electro-less copper plating. It is shown to be a high precision process with closely matched predicted and experimental performance, and shows great promise for flexible manufacturing of intricate beamforming networks.

By A. Périgaud, O. Tantot, N. Delhote, S. Verdeyme, S. Bila, D. Pacaud, L. Carpentier, J. Puech, L. Lapierre, and G. Carayon

This paper presents a concept for a tunable cavity resonator composed of a resonating cavity and a dielectric perturber. The tuning mechanism is obtained by varying the angle of rotation of the perturbers that are made by a ceramic additive manufacturing process (stereolithography).

By K. H. Church, N. B. Crane, P. I. Deffenbaugh, T. P. Ketterl, C. G. Neff, P. B. Nesbitt, J. T. Nussbaum, C. Perkowski, H. Tsang, J. Castro, J. Wang, and T. M. Weller

This paper presents direct digital manufacturing as an emerging technology for structural electronics, where lightweight plastic provides mechanical support as a fixture, a package, or a structural member and also hosts the electrical interconnects and devices, all in a contiguous fashion. Novel 3-D structures operating from C-band through Ku-band are presented.

By S. A. Nauroze, J. G. Hester, B. K. Tehrani, W. Su, J. Bito, R. Bahr, J. Kimionis, and M. M. Tentzeris

This paper provides a review of inkjet printing and its application to a wide range of RF/microwave and sensing applications. Examples of inkjet-printed devices that are presented include RFID tags, energy-harvesting circuits, passive microwave interconnects and packaging, and carbon-nanotube-based gas sensors.

By B. Zhang, Y.-X. Guo, H. Zirath, and Y. P. Zhang

In this paper, the authors discuss several additive manufacturing technologies that are available for high-frequency applications. An extensive experimental investigation of 3-D metal printing of waveguide components operating at up to 330 GHz highlights the potential advantages and open technological problems.

By H. Xin and M. Liang

This paper focuses on the application of the polymer-jetting process to the 3-D printing of novel sub/millimeter-wave components. Technological and design aspects are discussed in view of the development of highly integrated communication and sensing systems.

By W. J. Otter and S. Lucyszyn

In this paper, a hybrid manufacturing approach is presented that combines metallized passive components produced through the polymer-jetting process with active semiconductor devices. The potential for producing low-cost THz communication systems using this methodology is demonstrated with the successful development of a THz I-Q vector modulator.

Point of View

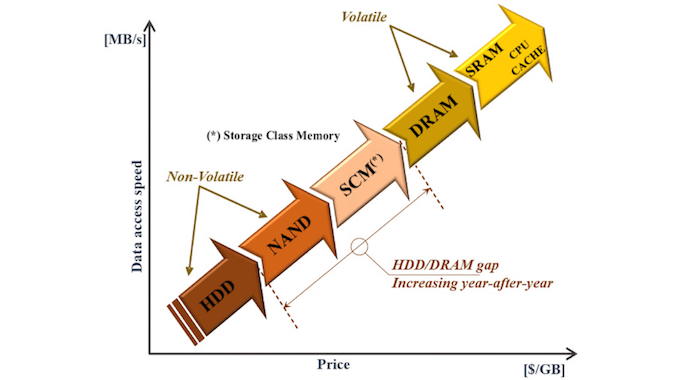

By Rino Micheloni

Scanning Our Past

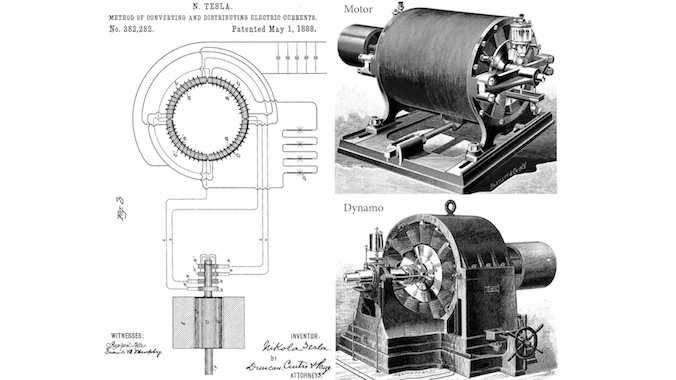

By Adam Allerhand